Different physical and chemical analyses are used to determine the optimal time for harvesting for subsequent processing.

Olives are harvested manually or mechanically depending on the type of crop, variety, grove conduction system, etc.

Immediately after harvest, olives are transported in boxes or bins to the mill or extraction plant. In order to obtain an excellent extra virgin olive oil, olives are processed within 24 hours of being harvested.

Olives are cleaned once they arrive at the mill. First, and by means of an air current, lighter elements such as leaves, stems, etc. are removed

Then, olives are washed in order to remove any traces of dirt or any other element that may remain on their surface. Perfectly cleaned olives are ready to be milled.

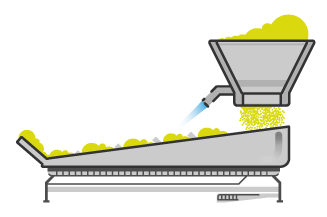

In the milling phase, olives are milled in a hammer mill that breaks vegetable tissue, tears the pulp and breaks the pit. Thus, a paste is obtained, which is then malaxed. The malaxation process seeks to speed up oil and pulp separation. To do so, the paste in the malaxer machine is subjected to a thermal-churn process at an average temperature of 30°C for a certain period.

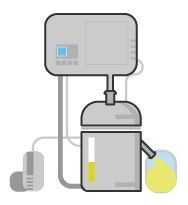

After the malaxation process, oil is strained from the rest of the components. To do so, the olive paste is subjected to a centrifugal force (decanter), which, due to the differences in density of the components, separates the oil from the other elements. After this, we can enjoy this delicious food.

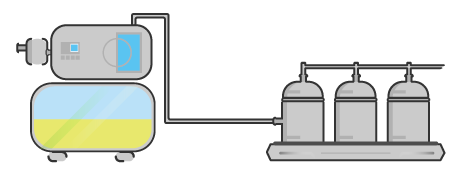

The oil obtained still contains solid debris and some humidity. That is why it goes through a filtration system. Later on, it is stored in stainless steel tanks, without any contact with the air and at constant, mild temperatures. Then, the olive oil is then ready for marketing.

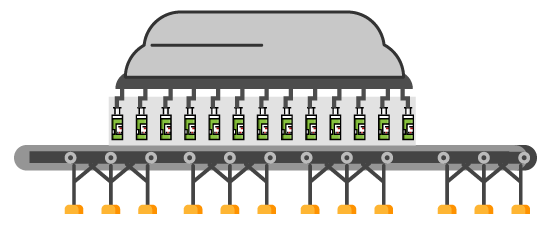

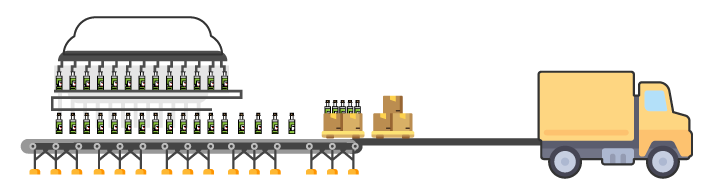

Once oil is extracted and the different blends are obtained, oil is fractioned into containers of different types and sizes. Labels are placed for the different types of olive oil and, after that, they are ready for marketing and distribution.