Olive harvesting

La cosecha de aceitunas comienza en el mes de enero. Las variedades que generalmente se utilizan para elaborar aceitunas verdes enteras son las siguientes: Manzanilla Fina, Aloreña, Hojiblanca y Picual.

La forma de recolección es manual.

01

02

02

The olives are placed in bins with a capacity of 550-600 kg and transported by trucks to the receiving yard of the industrial plant.

Transfer to factory

03

03

In this process, the glycoside known as "oleuropein," which is responsible for the olives' bitter taste, is removed from them.

Elimination of natural bitterness

04

04

Controlled natural fermentation process. Fermentation takes place within the first 90 days. pH, acidity, and residual sugars are monitored, as these vapors are essential for the proper development of lactic acid bacteria.

Lactic fermentation

05

05

Selection and classification

To complete the processing process, the fruit is sorted, removing any defective fruit, and then classified by size (caliber), i.e., the number of fruit per kilogram. CODEX STAN 66 standards are followed.

06

06

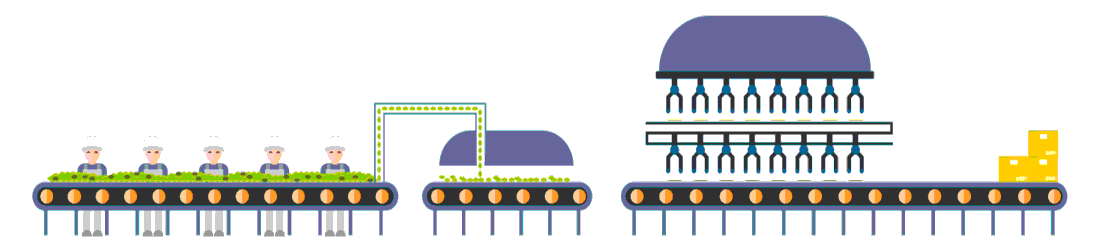

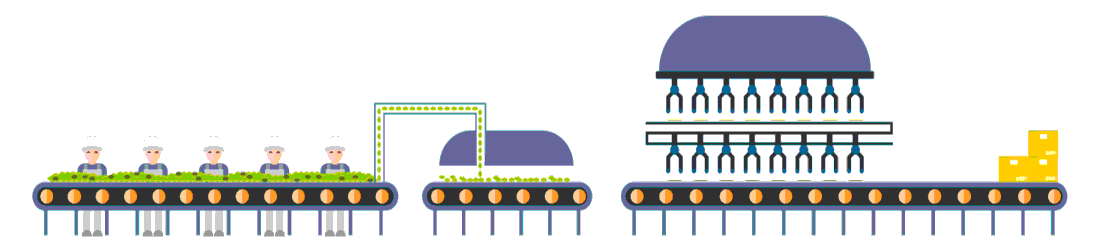

The fruits are subjected to different machining operations, the different processes are detailed below:

Pitting: This operation consists of separating the pit from the pulp, using automatic machines that pit the fruit at high speeds, then passing it to a densimeter that separates the pits by density and to an inspection belt, to separate the defective ones.

Slicing: After the olives have been pitted, they enter the slicing machine, which uses rotating blades to cut them perpendicular to the long axis into slices of relatively uniform thickness. They then pass through a sieve that removes any bits of pulp, leaving them ready for packaging.

Filling: The purpose of filling is to separate the pit from the pulp of the fruit and fill the space created with pepper paste.

Machining

7.1

7.1

En la sala de envasado se realiza el llenado del envase, primero se produce el dosificado volumétrico del producto y posteriormente el llenado de líquido de cobertura en forma simultánea con el sellado horizontal, vertical y superior de los envases sachet y doy pack, para estas operaciones la empresa cuenta con máquinas envasadoras automatizadas. En estas etapas también se produce la codificación de los envases.

Packed in sachet and doy pack

7.1

7.1

Packed in sachet and doy pack

Product presentation

7.2

7.2

Bottles are filled continuously on a linear filler, followed by filling with the covering liquid and subsequent capping of the container.

Packaged in a jar

Preservation method – Pasteurization

Once the bottles are capped, they enter a system suitable for pasteurizing glass containers of different sizes. It consists of an initial heating section, a standardized intermediate temperature section, and a final cooling section. It operates with an automatic loading device that allows all containers to enter the tunnel in an upright and orderly manner.

7.2

7.2

Packaged in a jar

Product presentation