Olives are harvested in January. The varieties generally used for whole green olives production are: Manzanilla Fina, Aloreña, Hojiblanca and Picual.

The harvest is performed manually.

Olives are placed in 550 – 600 kg. bins and are transported to the industrial plant goods yard.

In this operation, the "oleuropein" glycoside that causes olives to taste bitter is removed. To do so, a caustic soda solution is used. After this alkaline treatment, several washes are performed in order to remove the caustic soda solution.

Natural controlled lactic fermentation process. The fermentation time occurs during the first ninety days. pH, acidity and residual sugars are controlled, since the proper development of lactic acid bacteria depends on these values.

Final fermentation parameters:

In order to finish their conditioning, olives are selected, defective fruits are removed and then they are classified according to size (grade) according to the number of olives per kilo. The CODEX STAN 66 standard is used.

Olives are subject to different machining operations, which are detailed below:

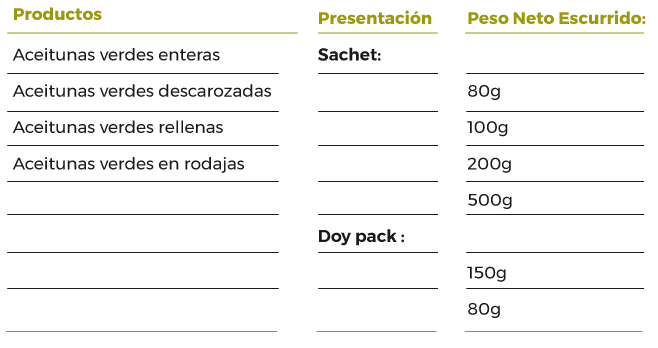

The packaging operation is performed using glass and/or flexible containers of different sizes and formats:

In the packaging room, containers are filled; first, the product volumetric dosing is performed and then, the coverage liquid is poured after which, pouches and doypacks are horizontally, vertically and top sealed. For these operations, the company has automated packaging machines. During these stages, containers are also coded.

The coverage liquid (packing brine) has the following final parameters:

Glass jar packaging is performed in a linear filling machine and in a continuous manner; then, the filling liquid is poured and the jar lid is placed.

Jars, once sealed, enter a machine suitable for pasteurizing different sized glass containers that consists in an initial heating area, an intermediate normal temperature sector and a final cooling sector. It works with an automatic loading device that allows all containers to enter the tunnel in a vertical, orderly manner.

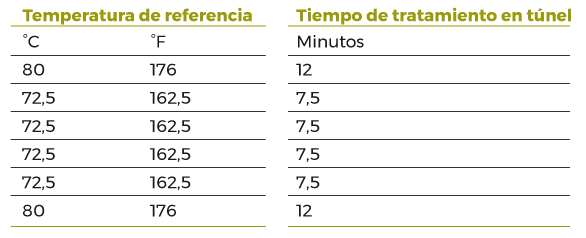

Treatment temperature and time parameters for each package type are the following:

The coverage liquid (packing brine) has the following final parameters: